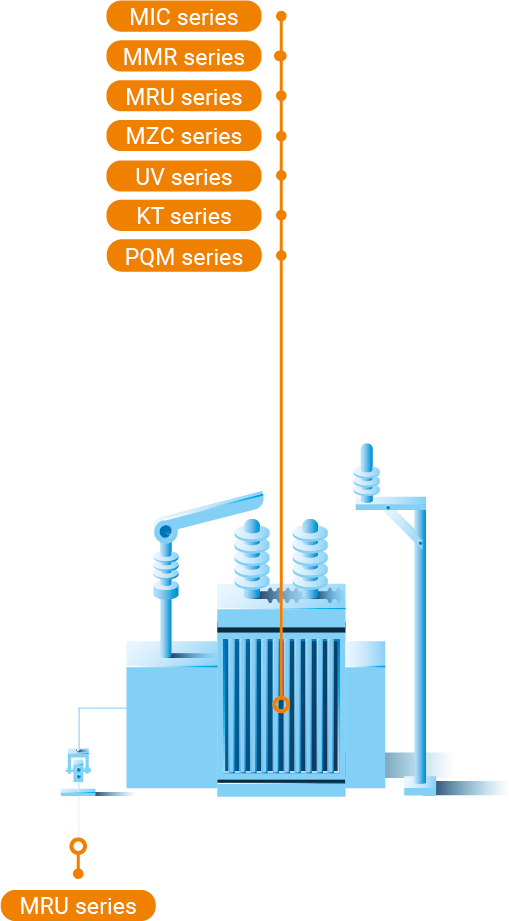

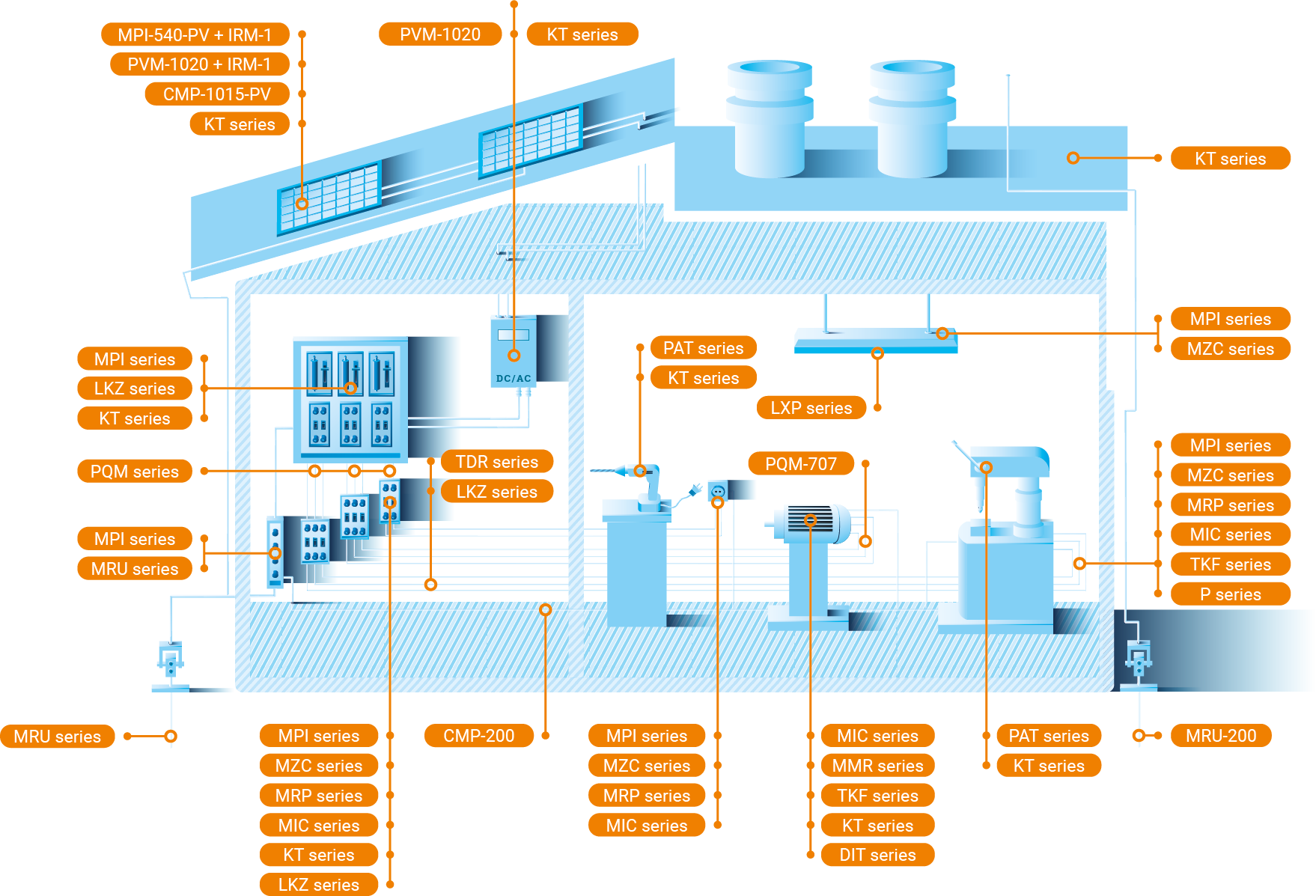

• Testing the continuity of: cables, contactors, relays, terminals.

• Measurement of mechanical drive starting current.

• Leakage current detection and measurement.

• Testing electrical parameters of devices powered from frequency inverter.

• Elimination of ghost voltage using low impedance (Low Z) voltage measurement.

• Verifying the presence or absence of voltage.

• AC and DC voltage measurement.

• Possibility of recording and reproducing electrical parameters on the production line and report creation.

• Remote access to the results in a mobile application.